Back in July I back a project https://www.indiegogo.com/projects/fuse-welding-filament-clamp-for-3d-printers. This looked like a neat idea. Basically it has a heater in the center of a Teflon block and a 1.75mm hole in it.

You put one end of filament in one side and another piece in the other push it through and it welds the two pieces together.

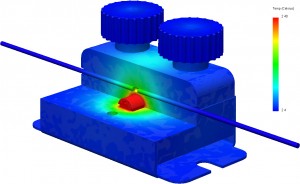

I received my Fuse today. Here is what I got.

Overall construction is good, no issues there. It looks well machined and assembled. Of coarse the next step it to plug it in an give it a try.

Overall construction is good, no issues there. It looks well machined and assembled. Of coarse the next step it to plug it in an give it a try.

This is my first attempt. It looks pretty ugly. The filament squished out into the slit around the 1.75mm channel. I had the screws tightened by hand the best I could. I did not try tightening them with pliers since I did not want to damage the thumb screws.

Needless to say its not idiot proof as it take some getting used to. Eventually after some practice I did start to get some usable joins. This is one of the better ones that I was able to do.

Same join as above compared to another one that is poor. You can see that the white part is bulged out.

Initial reaction based on 1 hr of use (yes I know that hardly makes me an expert).

The idea is solid;melt the ends and jam them together. This is a bit more challenging to pull off than you might think. To be fair I am using PLA which is probably the most difficult material to work with due to its low glass transition temperature. I found that the melting was difficult at best to control. PLA just loves to melt and deform as I learned from my experience with the http://www.filastruder.com/. This does not mean that I don’t think it can work. It does take some practice and lots of retries but with time I think that I can do much better. Unfortunately, due to its difficulty of use (right out of the box with no experience) I don’t think that we will see wade spread use of this product.

My next step will be to make some multicolored filament and do some printing with it. I am somewhat concerned with how the printer will handle the transition, especially when the filament is not perfectly consistent in diameter. From everything I know and read I dont think its going to be a big deal, assuming that there are not any bulges that make the filament jam in the hot-end.

More post on this topic to come.