I finally got around to testing the Filistruder and let just say it could have gone better. At first I got a tangled mess of PLA. Apparently extruding PLA was not the best choice on the first run of extruding since it turns out to be much harder to extrude consistently. I decided to do PLA since that is what I use in the Replicator 2. The filament that comes out of the nozzle is VERY pliable. I suspect that I can reduce this some by lowering the temperature but not by much. By supporting the filament by had and monitoring it very closely I ended up making some filament that might be usable (although its probably not worth the trouble).

Apparently extruding PLA was not the best choice on the first run of extruding since it turns out to be much harder to extrude consistently. I decided to do PLA since that is what I use in the Replicator 2. The filament that comes out of the nozzle is VERY pliable. I suspect that I can reduce this some by lowering the temperature but not by much. By supporting the filament by had and monitoring it very closely I ended up making some filament that might be usable (although its probably not worth the trouble).

On a positive note the filament that comes out is very clear and if I try really, hard supporting the filament by hand, it is consistent in color and shape. I am also surprised at how much filament is made from a small handful of pellets.

On a positive note the filament that comes out is very clear and if I try really, hard supporting the filament by hand, it is consistent in color and shape. I am also surprised at how much filament is made from a small handful of pellets.

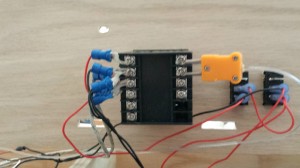

I think that I am going to have no choice setting up a filament puller similar to http://solidoodletips.wordpress.com/2013/05/07/filament-winder-intro he is using an optical sensor to gauge the speed at which the filament is being extruded to change the speed of the puller and spooler. This all seems like a lot of trouble but for now it is definitely worth it since making my own filament will reduce the price to 1/3 of the current price. I think that I may try to improve on the design by making the setup in a more vertical configuration since I have limited bench space. I also think that a wheel directly in front of the filistruder, something that has a high thermal mass like a big steel wheel, will help cool the filament in a much more consistent manor.

Ultimately I knew going in to this that this is not a consumer ready product but there is a lot of potential. The developers are actively working on improvement even while they are over run with activity in shipping out all the kickstarter rewards. So far the concept seems to be quite sound and I think that with some additions, making useable cheap filament should not bee too far away.