I have always wanted to make an electric motor from scratch and I finally got started. Here is the first prototype that I came up with.

(Sorry the video is rotated apparently wordpress cant rotate a video)

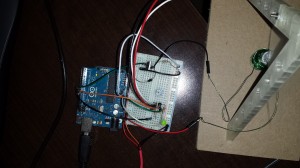

I did not want to mess with brushes so this is a single coil brushless motor with a neodymium magnet in the rotor/fan blade.

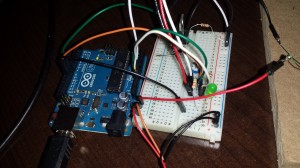

I am using a Hall Effect sensor attached to an Arduino to sense the position of the rotor and time the switching of the coil connected to an H-bridge. I also have a pot read as analog input on the Arduino to adjust the timing from when the Hall senses the magnet to when it pulses the coil.

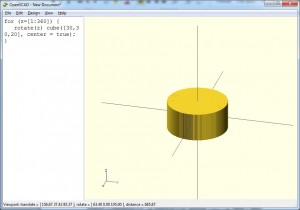

As you can see it works. Albeit it’s a bit slower than I would like. In the next prototype I will make the rotor propeller shaped so it can move are in a useful manner and I will make the motor more powerful (somehow).