I finally made some progress on the filament winders I got the parts for a while ago. So far I got the spool assembled:

Category Archives: Other Projects

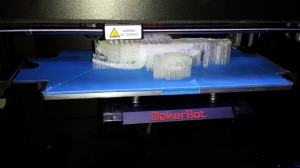

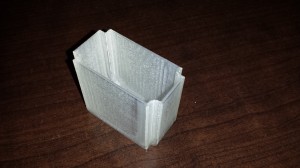

Small Parts Bin

I keep my assortment of screws in one of these https://www.grainger.com/Grainger/FLAMBEAU-Item-Adjustable-Compartment-Box-1NTH5?Pid=search

But some of the part I have are too small. They can slide under the plastic dividers. I printed some small bin that slide down inside the dividers to hold the small parts.

Practicing relaxation techniques can help you stay cheap viagra discount fit in more ways than you can even imagine.

They came out great. If you want to print some too you can find it here: http://www.thingiverse.com/thing:165313

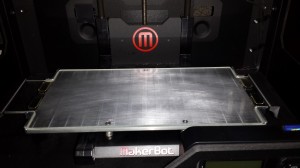

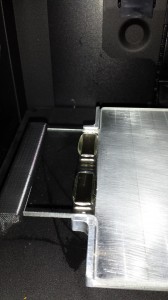

Aluminum Arms

I alluded to the getting Bottleworks Aluminum z axis arms (http://www.bctechnologicalsolutions.com/arm-upgrade/index.html) and now I have them and they are installed.

The install was NOT as simple as the heated build plate install. The instruction for the arms calls for a complete disassembly of the z axis to remove the OEM arms. This took the better part of 2 hours (possibly some interruptions in between) but it definitely a far cry from the 10 min install for the HBP.

I am very happy with the result. The product is very professionally made and the instructions are easy to follow. One unexpected result is that I am getting much more consistent sticking to the build plate. I suspect that the OEM arms were slightly flexing when the filament was getting laid down and this is no longer happening. Some minor adjustments to the height that I am leveling at allowed the parts to pull off more easily.

Once again hats off to Bottleworks for another great product.

Apple Disk 2 Emulator case

I have been commissioned by Koichi over at http://tulip-house.ddo.jp/digital/SDISK2/english.html to make a case for his new disk 2 emulator board. He was nice enough to send me on of his boards for reference. One thing I did not realize is that it was going to be so small.

Thanks to my friend Alex and his fellow Apple collector Geoffery for acquiring an original that I can digitize to try to get the features of the case. I started by trying 123D Catch and I think I am going to need more work on getting it right. It is also possible that I may have to abandon this approach and go back to the old measure and draw.

Stay tuned for updates on my progress on digitizing this classic.

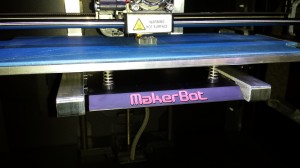

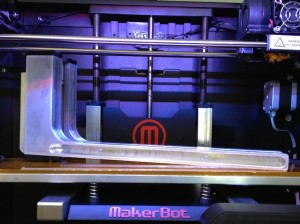

Heated Build Plate

I received the heated build plate I order for my replicator 2 (http://bctechnologicalsolutions.com/hbp/index.html) and I must say that it is great. Bottleworks really did a fantastic job making a professional product. Installation was easy and there was no modification to my Replicator 2 for the installation. Everything works as designed.

I generally use Makerware for prints and there is a modification to the device definition required to force Makerware to allow configuration of the platform temperature for a build. Thanks to Guidozelf for figuring this out (Makerbot Operators). Basically it involves modifying three section in the in C:\Program Files (x86)\MakerBot\MakerWare\s3g\profiles\ Replicator2.json related to the heated platform. These sections are copy and pasted from Replicator2X.json in the same directory for reference.

This is my file that is working (no mods from the default except the HBP sections):

One thing I noticed when testing the heat is that the stock z-arms sag quite significantly when the build plate is heated. I was planning on buying his aluminum z arms http://www.bctechnologicalsolutions.com/arm-upgrade/index.html I just didn’t expect to buy them so soon. Oh well they are on order and hopefully I will get them soon. No worries printing with PLA does not need heat (most of the time).

KIFA Presentation Wed. September 25 at 6:30PM

I will be giving a presentation on 3D printing for the Kent Island Federation of Arts (KIFA) this coming Wednesday at 6:30. This will be mostly the same presentation that I gave at Unallocated space back in June (http://www.3dprintmd.com/print/reminder-and-slides-intro-to-3d-printing-and-3d-design-fri-june-21-7pm-10pm-unallocated-space/). It is very cool to share 3D printing with the world… after all that what this site is all about!

KIFA Member’s Meeting

When: Wednesday, September 25, 2013 at 6:30

Where: Kent Island Branch Public Library, meeting room

In the meantime I designed a key chain for the presentation. Enjoy!

It’s too easy

Another lesson from: Is it plastic? I can make that!

I was working on my RV this weekend and found the plastic part on the drawer rail was broken. The screw flange on one side was broken and the other side was completely missing. Less than 10 mins later I had a design and got my printer working as I went back to doing other things. It only took 37 mins to print and another 5 mins to install. In total it was easily less than the time it would have taken me to drive to the store and back. Not only that, it only cost about $0.25 in plastic. I am starting to wonder why everyone doesn’t have a 3D printer now days. Maybe if I keep sharing these easy wins people will start to pay attention.

Another recap update

I got the parts but not the time

I printed all the parts for the filament puller based on http://solidoodletips.wordpress.com/2013/05/07/filament-winder-intro and the parts listed on the Thingiverse http://www.thingiverse.com/thing:81662. All I need now is the time to work on it. I was able to make the frame that I am going to attach all the parts to but that is about it. You can see that I am going to try to stack the Filastruder on top which is different and I am not exactly sure that it’s going to work. The problem that I see when is horizontal is that one, it takes up lots of space and two, PLA which is what I am most interested in extruding, is extremely playable when it comes out of the Filastruder. I was going to try to put a thermal mass wheel right at the nozzle to try to cool and shape the filament before winding. I hope it works.

More XYZ

I have been printing away from jobs coming from http://www.makexyz.com/printer/michael_mcco. This seems like a very convenient way to get print jobs. The only issue that I could complain about is that the users requesting prints most of the time want 3D design as well. I don’t mind doing the design work and I am getting much better at it but, it is quite time consuming and I really don’t know how to charge for the design work. If I charge a flat hourly rate I think that it will make people not want to get items printed but if I charge an item design fee it really does not cover all the time it takes to do the design. Either way I am happy to do the work because I do enjoy doing it. We will have to see how long that lasts. I can say that I have made enough money back from my printer to upgrade (see next paragraph).

We need more heat Scotty

I made enough money from my printer to upgrade to a heated build plate (I probably would have bought it regardless). http://bctechnologicalsolutions.com/hbp/index.html.  I have been waiting for a kit like this pretty much as soon as I got my printer. I ordered the required larger PSU (huge 9.1A) for my printer from http://www.jameco.com/webapp/wcs/stores/servlet/Product_10001_10001_2099286_-1 it’s a drop in replacement with the correct connector and got it right away.

I have been waiting for a kit like this pretty much as soon as I got my printer. I ordered the required larger PSU (huge 9.1A) for my printer from http://www.jameco.com/webapp/wcs/stores/servlet/Product_10001_10001_2099286_-1 it’s a drop in replacement with the correct connector and got it right away.

I order the build plate last week and it is a bit backordered with delivery in 3-4 weeks. This will allow printing with ABS on my replicator 2 and it will reduce warping of PLA when doing high infill printing.

I order the build plate last week and it is a bit backordered with delivery in 3-4 weeks. This will allow printing with ABS on my replicator 2 and it will reduce warping of PLA when doing high infill printing.

Store is open

I finally opened a store for the 3D Printed Case for Analog RGB to Component Adapter I designed a while back http://www.3dprintmd.com/print/3d-printed-items-for-sale/. I have sold a few since the maker of the kit (Koichi ) linked to my site direct from his http://tulip-house.ddo.jp/digital/english.html. I plan on putting up a few more items that I have designed that I want to keep the controls over. I think that this might be a way to earn back some of the design time that I put into it by spreading out the cost of the design over hopefully a bunch of prints. Koichi also asked me to work with him on designing a case for his DISK II board http://tulip-house.ddo.jp/digital/SDISK2/english.html which I am excited to do.

That’s it for now I have other stuff but I have to keep some it reserve for future posts 🙂

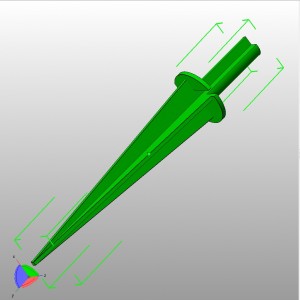

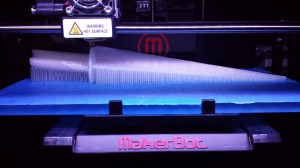

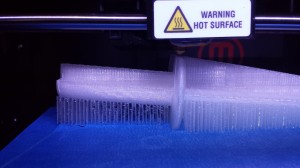

Another 3D printed win

The walkway lighting that I have in the front of my house is a bit old. It is probably original to the house. The posts in the ground appear to be made from aluminum and have corroded and several of them have fallen down. Time to print some new ones!

I am getting quite quick at 3D design and replicating the existing post only took about 20mins.

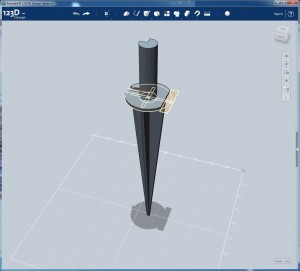

If you are familiar with my previous posts on the extrusion method here is the 2D sketch that I extruded from. And here is the extruded result. I used the tweak tool to drag the bottom + shape into a point.

And here is the extruded result. I used the tweak tool to drag the bottom + shape into a point. Off to the printer and here is the result

Off to the printer and here is the result

Summay of the last few weeks

Boo on me it’s been almost three weeks since my last post. If anyone is listening; Sorry! I have had a lot going on in the last few weeks here is a summary.

Raspberry Pi cases:

I got an order for 6 raspberry pi cases in several colors that have been keeping me (and my printer) busy recently. A friend of mine is going to the http://www.kansasfest.org/ and they will be doing something with raspberry pis. He posted in the forums if anyone wants a printed pi case for $8 and he got an order for 6.

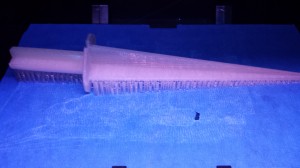

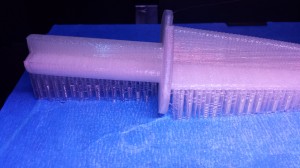

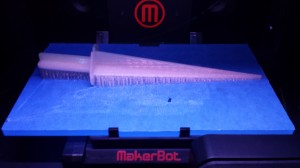

Filistruder:

I was able to print a hopper and a replacement part for one that broken when I was assembling. The hopper is actually an upgraded one that I found on the thingiverse and it is very nice. I am so far very happy with the design and it fits perfectly. I still have yet to extrude any filament but I hope to soon. I will post my results once I get it going.

Free upgrade Replicator 2 filament extruder:

I finally received the free upgrade for the Replicator 2 filament extruder after waiting nearly 8 weeks (they said it would be 6). http://store.makerbot.com/extruder-upgrade.html?utm_source=MakerBot+Customers&utm_campaign=43f102128a-Replicator_2_Extruder_Upgrade_5_14_2013&utm_medium=email&utm_term=0_2a6be7f082-43f102128a-407817429

The installation was quite easy and it is working great. I have printed 3 pi cases with the new parts and everything is working fine so far.

More work from makexyz:

I got a few more orders from makexyz. This seems to be working out fine. I have made a few buck from these jobs but nothing to write home about. I never really thought I would make the big buck doing this and I only expected to supplement the cost of the printer. Any money I can get back for my investment is fine by me. Plus I enjoy doing the work (not so much the shipping and what not).

3D printing presentation on youtube:

It’s true I am on youtube http://www.youtube.com/watch?

KIFA 3D printing presentation:

I will be giving my presentation on 3D printing again to the Kent Island Federation of Arts at the KI Library on Sep 25, 6:30 PM – 8:30 PM. I am not sure if this is open to the public or not I will try to post back once I figure this out.

Wow this is a long post but that’s what I get for not posting for three weeks.